In the realm of industrial cutting machinery, the horizontal band saw machine has emerged as a preferred choice for many manufacturers and workshop operators. This preference is not without reason, as horizontal band saw machines offer a multitude of advantages over their vertical counterparts. The purpose of this article is to explore these benefits in detail, highlighting why horizontal band saw machines are often considered superior for certain cutting tasks.

One of the primary advantages of horizontal band saw machines is their ability to handle a wide range of materials with ease. The horizontal orientation of the blade allows for a more stable and consistent cut, which is particularly beneficial when dealing with longer or irregularly shaped materials. This stability is a direct result of the blade's orientation, which reduces the likelihood of material warping or bending during the cutting process.

Another significant advantage of horizontal band saw machines is their efficiency in terms of material usage. The horizontal blade path minimizes the amount of material that is wasted during the cutting process. This is especially important in industries where material costs are high, as it can lead to significant savings over time. The reduced material waste also contributes to a more sustainable and environmentally friendly production process.

In terms of operator safety, horizontal band saw machines offer a more controlled and predictable cutting environment. The horizontal orientation of the blade makes it easier for operators to monitor the cutting process, reducing the risk of accidents. Additionally, many horizontal band saw machines are equipped with safety features such as blade guards and emergency stop buttons, further enhancing the safety of the operation.

The precision and accuracy of cuts made by horizontal band saw machines are also noteworthy. The downward cutting motion of the blade allows for a more controlled and precise cut, which is essential in applications where close tolerances are required. This precision is further enhanced by the use of high-quality blades that are specifically designed for horizontal band saw machines.

Maintenance and blade changes are also more straightforward with horizontal band saw machines. The accessibility of the blade and other components makes it easier for operators to perform routine maintenance and replace blades when necessary. This not only reduces downtime but also ensures that the machine remains in optimal working condition.

Efficiency is another area where horizontal band saw machines excel. The high cutting speed and smooth operation of these machines allow for quick turnaround times, which is crucial in high-production environments. The ability to cut through materials quickly and accurately without compromising on quality makes horizontal band saw machines an attractive option for many industries.

Versatility is yet another advantage that horizontal band saw machines bring to the table. These machines can be adapted to cut a variety of materials, including metals, plastics, and even some composites. This adaptability allows businesses to diversify their offerings without needing to invest in additional machinery.

In conclusion, the horizontal band saw machine's advantages over vertical models are manifold. From improved material handling and efficiency to enhanced safety and precision, horizontal band saw machines offer a compelling choice for businesses looking to optimize their cutting operations. As industries continue to evolve and the demand for high-quality, precision cutting increases, the horizontal band saw machine is likely to remain a popular and effective solution.

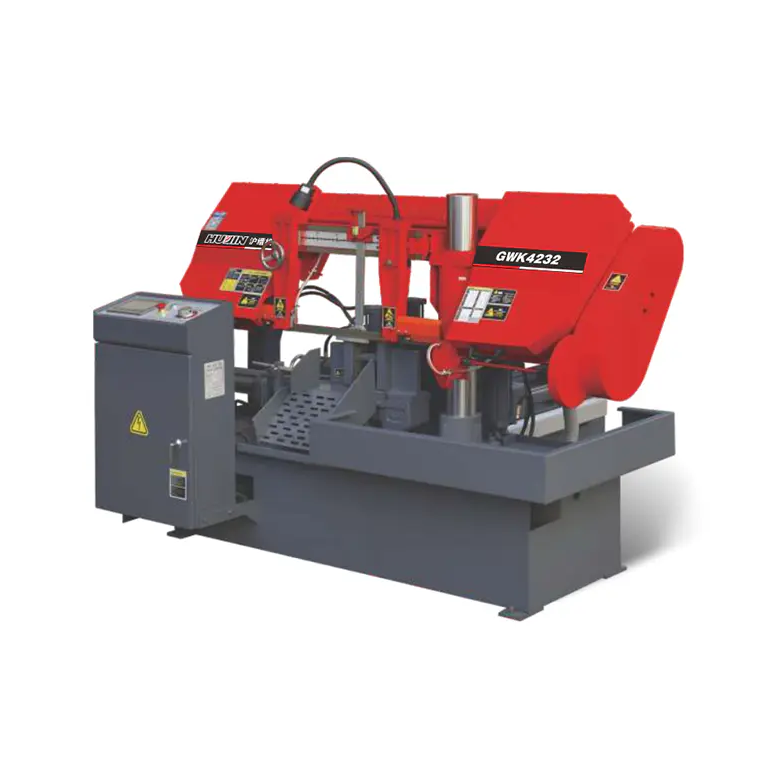

Cutting Capacity(mm) : Round material Φ500 Plate 500x500

Blade speed(m/min): 30,60,80

Blade Size(mm):1.3*41*6200

Single feeding travel(mm):500

Motor main output(kw): 4-6

Hydraulic(kw):1.5

Coolant pump(kw): 0.09

Machine Size(LxWxH)(mm): 3000*2200*1950