The compatibility of Board to Board Power Connectors is a critical aspect of their functionality within the realm of electronics. As devices continue to evolve at a rapid pace, the connectors that facilitate power and data transmission between circuit boards must keep up with these advancements. Compatibility is not just about fitting into a physical space; it encompasses the ability of these connectors to work seamlessly with a variety of systems, protocols, and standards.

Board to Board Power Connectors are designed to provide a reliable electrical connection between two PCBs (Printed Circuit Boards) in close proximity. Their compatibility is determined by several factors, including pin configuration, current carrying capacity, voltage ratings, and physical dimensions. These connectors must be able to accommodate different board layouts, materials, and manufacturing processes without compromising performance.

In the context of compatibility, Board to Board Power Connectors must be adaptable to various electronic devices, from small consumer electronics to large industrial machinery. This adaptability is achieved through standardized designs that allow for interchangeability across different manufacturers and product lines. However, the challenge lies in maintaining compatibility while also incorporating advancements in technology, such as higher power densities and faster data transfer rates.

One of the key aspects of Board to Board Power Connector compatibility is the ability to handle different voltage and current requirements. As technology advances, the demand for higher power and faster data transmission increases. This puts pressure on connectors to evolve, with some designs incorporating multiple power and signal paths to accommodate these needs. The connectors must also be able to manage the heat generated by these increased loads without degrading performance.

Another critical factor in the compatibility of Board to Board Power Connectors is their physical design. The connectors must be robust enough to withstand the stresses of daily use, including repeated insertions and removals, while also being small enough to fit into increasingly compact devices. This balance between size and durability is a constant challenge for manufacturers.

In addition to physical and electrical compatibility, Board to Board Power Connectors must also be compatible with the software and protocols used in modern electronics. This includes support for various communication standards, such as USB, HDMI, and PCIe, which require specific connector configurations and signal integrity.

The compatibility of Board to Board Power Connectors is also influenced by the materials used in their construction. Connectors must be made from materials that resist corrosion and wear, ensuring long-term reliability in a variety of environments. This is particularly important in applications where the connectors are exposed to harsh conditions, such as high humidity or extreme temperatures.

In conclusion, the compatibility of Board to Board Power Connectors is a multifaceted issue that involves physical design, electrical specifications, and material properties. As technology continues to evolve, the connectors must adapt to maintain their compatibility with new systems and standards. This requires a deep understanding of the challenges faced by electronic devices and a commitment to innovation in connector design and manufacturing. By addressing these compatibility issues, Board to Board Power Connectors can continue to play a vital role in the development of next-generation electronic systems.

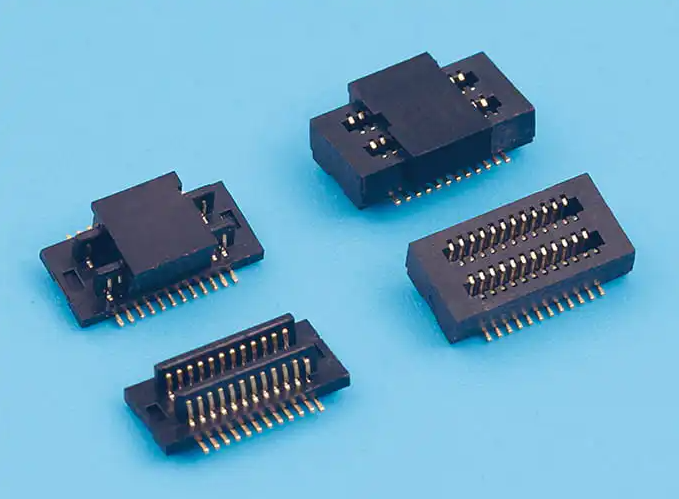

1、CKT: 2*5Pin to 2*40Pin

2、Current rating: 0.5A AC/DC

3、Voltage rating(max): 100V, AC/DC

4、Working Temperature: -25C~ +85C,

(Including temperature rise in applying electrical current)

5、Contact resistance: value s20mΩ

After environmental testing s40mΩ

6、Insulation resistance: 21000MΩ

7、Withstand voltage: 200VAC(rms)

8、Applicable PCB board thickness: 1.6mm to 2.0mm