The WTB Wire to Board Connector is a critical component in the realm of electronics, facilitating the connection between wires and circuit boards. Its performance under high-temperature conditions is a significant concern for industries where equipment is subjected to thermal stress. This article delves into the resilience and performance of WTB Wire to Board Connectors when exposed to elevated temperatures.

The ability of a WTB Wire to Board Connector to maintain its integrity and functionality in high-temperature environments is crucial for applications ranging from automotive electronics to industrial machinery. The connectors must not only withstand the heat but also ensure signal integrity and mechanical stability, which are essential for the proper operation of the connected devices.

Material composition plays a vital role in the high-temperature performance of WTB Wire to Board Connectors. Connectors made from materials with high thermal resistance, such as certain grades of plastic and metal alloys, can better endure heat without degrading. These materials maintain their structural integrity and electrical properties even when the temperature rises, ensuring that the connectors continue to function as intended.

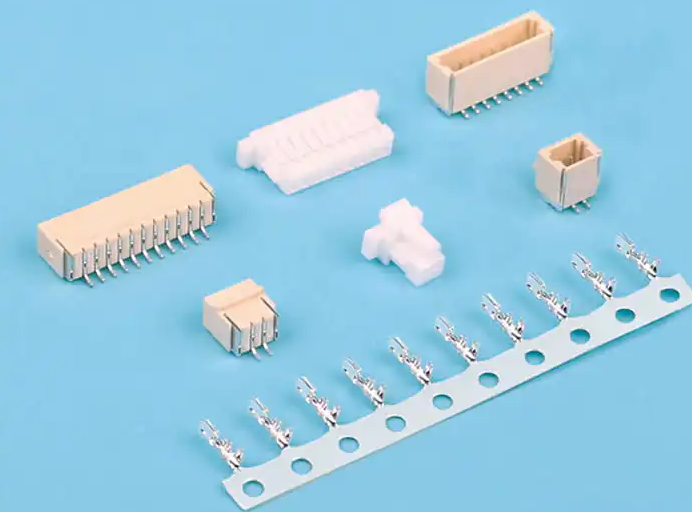

Another aspect to consider is the design of the WTB Wire to Board Connector. Connectors with a compact design and proper heat dissipation mechanisms can manage heat more effectively, reducing the risk of overheating and potential damage. Additionally, the use of heat-resistant insulation and shielding can protect the internal components of the connector from the adverse effects of high temperatures.

The performance of WTB Wire to Board Connectors in high-temperature conditions is also influenced by the manufacturing process. High-quality connectors undergo rigorous testing and quality control measures to ensure that they can withstand the specified temperature range. This includes stress tests that simulate the connector's performance under extreme heat, providing valuable data on its durability and reliability.

In practical applications, the performance of WTB Wire to Board Connectors in high-temperature environments is often a determining factor in the success of a product. For instance, in automotive applications, connectors must endure the heat generated by the engine and the external temperature variations. Similarly, in aerospace and military applications, connectors must be able to function in the harsh conditions of high altitudes and rapid temperature changes.

To further enhance the high-temperature performance of WTB Wire to Board Connectors, some manufacturers incorporate additional features such as heat sinks or thermal interfaces. These components help to dissipate heat away from the connector, reducing the thermal load and prolonging the connector's lifespan.

In conclusion, the high-temperature performance of WTB Wire to Board Connectors is a multifaceted issue that involves material selection, design, manufacturing processes, and additional thermal management solutions. As technology advances and the demands on electronic components increase, the development of WTB Wire to Board Connectors that can perform reliably in high-temperature conditions becomes increasingly important. By understanding the factors that contribute to their performance and implementing strategies to mitigate the effects of heat, manufacturers can ensure that their connectors meet the stringent requirements of high-temperature applications.

1、CKT: 2Pin to 25Pin

2、Current rating: 0.5A AC/DC

3、Voltage rating(max): 30V, AC/DC

4、Working Temperature: -25°C~+85C,

(Including temperature rise in applying electrical current)

5、Contact resistance: Initial value s20mΩ

After environmental testing≤40mΩ

6、Insulation resistance: 2100MΩ

7、Withstand voltage: 200VAC(rms)

8、Applicable wire: AWG #32 to #28

9、Applicable PCB board thickness: 1.6mm to 2.0mm