Quality assurance is a fundamental aspect of the manufacturing process, and it is particularly crucial when it comes to Plastic Industrial Tray Mould. These molds are integral to the production of a wide range of plastic trays used across various industries, from food packaging to electronics. Ensuring the quality of Plastic Industrial Tray Moulds is not just about meeting the immediate needs of the product but also about sustaining the reputation of the manufacturer and the reliability of the end product.

The first step in ensuring the quality of Plastic Industrial Tray Moulds is to start with the selection of the right materials. High-quality steel is often used for mold construction due to its durability and ability to withstand the high pressures and temperatures involved in the injection molding process. The material selection must also consider the specific requirements of the plastic being used, such as its melting point and the chemical properties that could affect the mold's longevity.

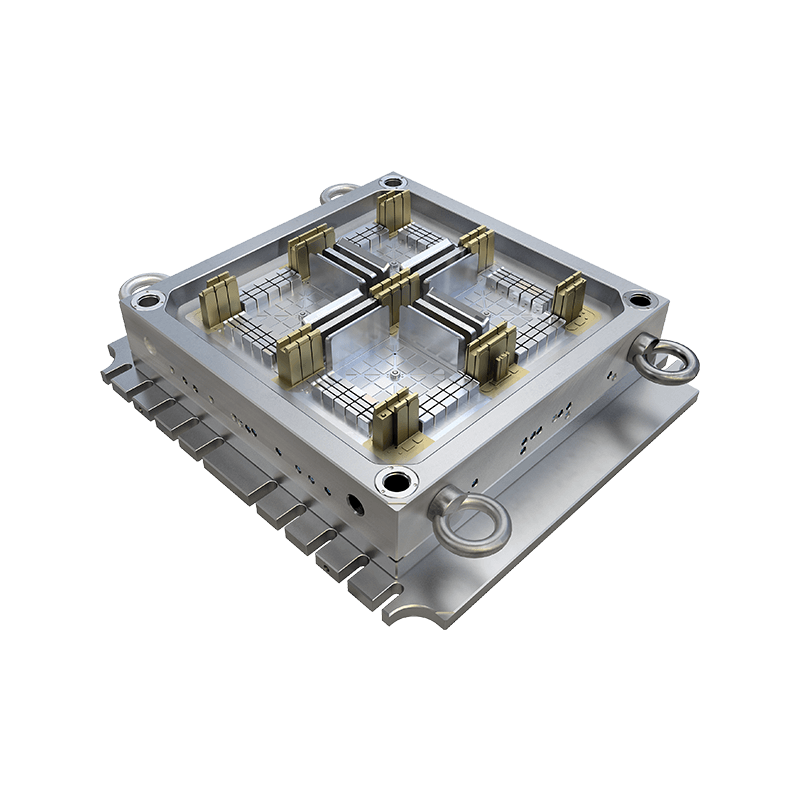

Design precision is another critical factor in the quality of Plastic Industrial Tray Moulds. The design must be accurate to ensure that the molded trays meet the required specifications. This involves using advanced computer-aided design (CAD) software to create detailed blueprints of the mold, which can then be used to guide the manufacturing process. Sophisticated design also includes considerations for the cooling system, which is essential for the efficient removal of heat from the mold to prevent warping and ensure consistent product dimensions.

The manufacturing process itself must be tightly controlled to maintain the quality of Plastic Industrial Tray Moulds. This includes the use of precision machining techniques to create the mold cavities and cores. The machining process must be carried out with extreme accuracy to ensure that the mold's dimensions are consistent with the design specifications. Additionally, the surface finish of the mold must be smooth to prevent any defects in the final plastic tray, such as surface imperfections or uneven walls.

Inspection and testing are vital components of the quality assurance process for Plastic Industrial Tray Moulds. After the mold is manufactured, it must undergo rigorous testing to ensure that it functions correctly and produces trays that meet the required specifications. This can involve testing the mold's ability to withstand high pressures, its temperature tolerance, and its overall structural integrity. Any defects or inconsistencies found during testing must be addressed before the mold is used in production.

Maintenance and upkeep of the Plastic Industrial Tray Moulds are also essential for maintaining quality. Regular inspections and maintenance can help identify any potential issues before they become critical problems. This includes checking for wear and tear, ensuring that the cooling system is functioning efficiently, and making any necessary adjustments to the mold to maintain its accuracy.

Finally, the quality of Plastic Industrial Tray Moulds can be further enhanced through continuous improvement efforts. This involves regularly reviewing the manufacturing process, seeking feedback from customers, and staying up-to-date with the latest advancements in-mold technology. By implementing new techniques and technologies, manufacturers can improve the efficiency and quality of their Plastic Industrial Tray Moulds, ensuring that they remain competitive in the market.

In conclusion, ensuring the quality of Plastic Industrial Tray Moulds is a multifaceted process that involves careful material selection, precise design, controlled manufacturing, thorough inspection and testing, regular maintenance, and a commitment to continuous improvement. By focusing on these areas, manufacturers can produce high-quality molds that meet the needs of their customers and maintain a strong reputation in the industry.