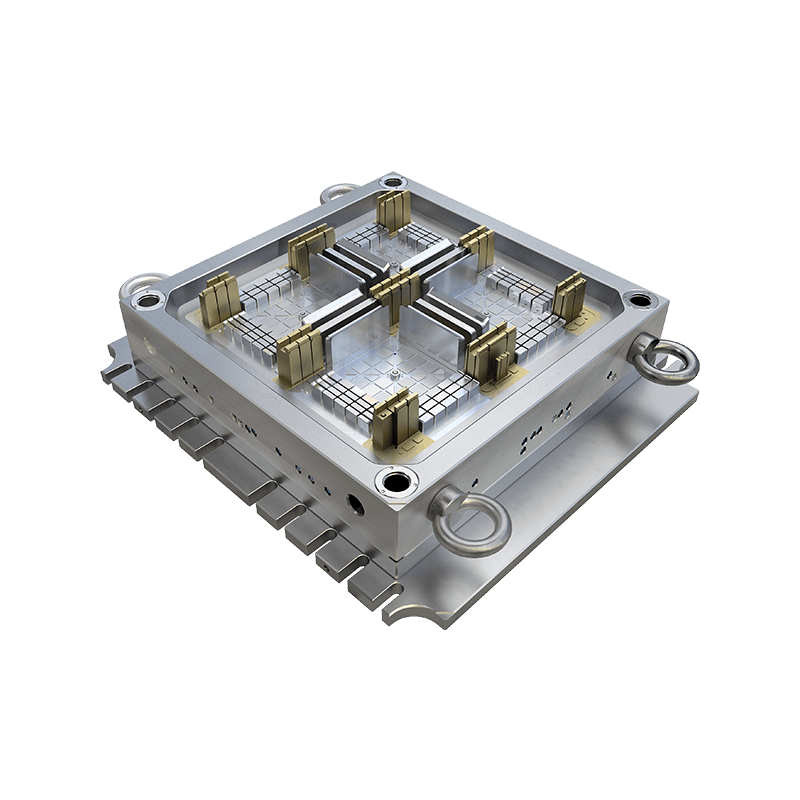

In the intricate process of manufacturing, the choice of materials is paramount, especially when it comes to the creation of the Plastic Industrial Container Mould. These moulds are the backbone of producing a wide array of industrial containers that serve various purposes, from storage to transportation. The materials used in the construction of these moulds directly influence the quality, durability, and functionality of the final product. This article delves into the materials commonly employed in the making of Plastic Industrial Container Moulds and the advantages these materials offer in the production of high-quality industrial containers.

The Materials of Choice for Plastic Industrial Container Moulds

The primary materials used in the construction of Plastic Industrial Container Moulds are selected for their specific properties that cater to the demands of industrial container production. These materials include:

1. Steel: Steel is a popular choice due to its strength, durability, and heat resistance. It is often used in the form of tool steel, which is designed to withstand the rigours of injection moulding processes. The use of steel in Plastic Industrial Container Moulds ensures that the moulds can endure high pressures and temperatures without deformation, leading to the production of containers with precise dimensions and uniform wall thickness.

2. Aluminum: Aluminum moulds are known for their lightweight and excellent thermal conductivity. This makes them ideal for applications where quick heat dissipation is necessary, such as in the production of large or complex container shapes. Aluminium moulds also offer a cost-effective alternative to steel, without compromising on the quality of the final product.

3. Plastic: In some cases, Plastic Industrial Container Moulds themselves can be made from high-grade plastics. These moulds are typically used for low-volume production or for prototyping new container designs. The advantage of plastic moulds lies in their ease of fabrication and the ability to create intricate details that might be challenging with metal moulds.

Advantages of Material Selection in Mould Production

The choice of material for Plastic Industrial Container Moulds offers several advantages that contribute to the production of high-quality industrial containers:

1. Precision and Consistency: High-quality materials like tool steel ensure that the moulds maintain their shape and dimensions over time. This leads to the consistent production of containers with uniform quality, which is crucial for industrial applications where reliability is key.

2. Durability and Longevity: Materials like steel and aluminium are chosen for their ability to withstand the wear and tear of the injection moulding process. This results in longer mould life, reducing the need for frequent replacements and minimizing production downtime.

3. Heat Resistance: The ability of the mould material to handle high temperatures is essential, especially in the case of plastic containers that may require heat during the moulding process. Materials with high heat resistance prevent thermal deformation, ensuring the integrity of the container's design.

4. Detail Retention: The material's capacity to retain fine details is crucial for creating containers with complex geometries or intricate features. High-quality materials allow for the production of moulds that can capture these details without loss of quality.

5. Cost-Effectiveness: While initial investment in materials like steel may be higher, the long-term benefits of durability and precision can lead to cost savings. Additionally, materials like aluminium and certain plastics can offer a more cost-effective solution without compromising on quality.

The selection of materials for the construction of Plastic Industrial Container Moulds is a critical decision that impacts the quality, functionality, and efficiency of industrial container production. By choosing materials that offer strength, durability, heat resistance, and precision, manufacturers can ensure the production of containers that meet the rigorous demands of industrial applications. The advantages of material selection in Plastic Industrial Container Moulds are manifold, contributing to the creation of containers that are reliable, consistent, and of high quality, thereby enhancing the overall productivity and success of industrial operations.