Injection mold manufacturers play a crucial role in the production and design of plastic chair stool molds. These manufacturers are responsible for creating high-quality molds that meet the specifications and requirements of the clients. The plastic chair stool mold industry is constantly evolving and manufacturers are continuously innovating to produce efficient and durable molds. In this article, we will delve into the world of injection mold manufacturers and the significance of plastic chair stool molds.

Plastic Chair Stool Mould - An Essential Component:

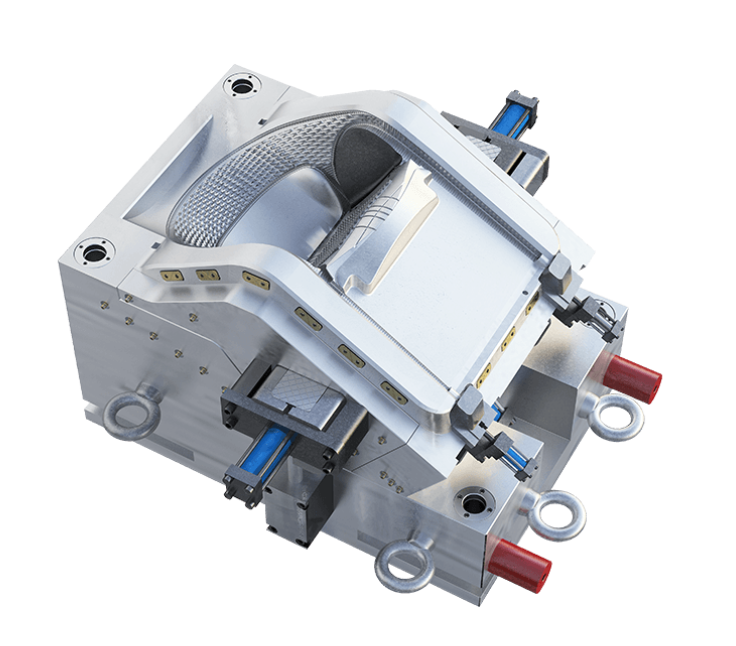

Plastic chair stool molds are essential for the production of stylish and functional chairs and stools. These molds are carefully designed to create accurately shaped and impeccably finished products. Injection mold manufacturers specialize in creating molds that can withstand the high pressure and temperature involved in the injection molding process. They understand the importance of precision and durability in plastic chair stool molds, as these factors directly impact the quality and longevity of the final products.

Injection Mold Manufacturers - Experts in Craftsmanship:

Injection mold manufacturers are experts in the field of mold design and fabrication. These professionals possess an in-depth understanding of different types of plastic materials, their properties, and behavior during the molding process. They have the knowledge and expertise to select the appropriate mold material and design, ensuring enough efficiency and durability. Injection mold manufacturers utilize advanced technologies and machinery to fabricate molds with intricate designs and patterns, resulting in high-quality plastic chair stools.

Technological Advancement and InnovationWith advancements in technology, injection mold manufacturers have significantly improved their processes and capabilities. Computer-aided design (CAD software allows manufacturers to create 3D models and simulations of the plastic chair stool molds, enabling better visualization and evaluation. Additionally, numerical control (CNC) machines have revolutionized the production process by enhancing precision and reducing lead times. Injection mold manufacturers constantly strive to improve their techniques, materials, and machinery, ultimately benefiting the clients with superior products.

Quality Control and Customer Satisfaction:

Injection mold manufacturers understand the importance of quality control and customer satisfaction. They perform stringent inspections and tests on each mold to ensure it meets the required standards. Manufacturers also work closely with clients, collaborating on design modifications and enhancements, to ensure the molds meet their specific needs. By prioritizing quality and customer satisfaction, injection mold manufacturers build strong and long-lasting partnerships with their clients.

Environmental Considerations:

Injection mold manufacturers also take environmental considerations into account. They strive to reduce waste and utilize recycled and eco-friendly materials wherever possible. These practices not only contribute to a greener environment but also enhance the reputation of the manufacturers as responsible members of the industry.

Injection mold manufacturers are crucial players in the production of high-quality plastic chair stool molds. These experts possess the knowledge, skills, and technology required to create molds that meet the clients' specifications and requirements. By continuously innovating and utilizing advanced technologies, they strive to deliver efficient and durable molds. With a focus on quality control and customer satisfaction, these manufacturers play a vital role in the plastic chair stool industry, creating stylish and functional products.